"QUANTUM SHOT" #268

"QUANTUM SHOT" #268Article by Paul Schilperoord, Link

Exciting Innovations in Transportation

Welcome are new contributing writer (future transportation technologies) Paul Schilperoord, whose book "Future Tech - Innovations in Transportation" was published in 2006 by Octopus Design / Black Dog Publishing and received many enthusiastic reviews. He's working on the next book already, about some mysterious aspects of German car-making. We are honored to have Paul in our team of writers, with projected monthly features on various cool "future tech".

"Future Tech" aims to present you with a realistic view of the future, based on concepts and prototypes for future vehicles, which are currently in serious development.

"Future Tech" aims to present you with a realistic view of the future, based on concepts and prototypes for future vehicles, which are currently in serious development. We are going to highlight a few examples from each section of the book. You will also see some material not found in the book, provided exclusively for DRB. Our sincere hope is that we are going to see at least some of these concepts mass-produced one day.

ROAD TRANSPORT:

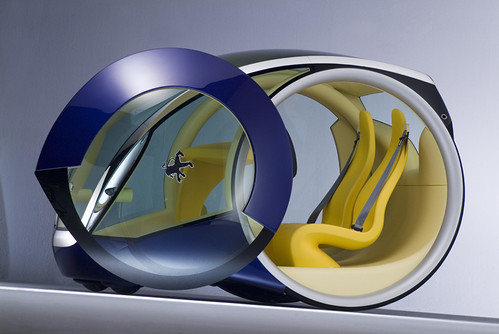

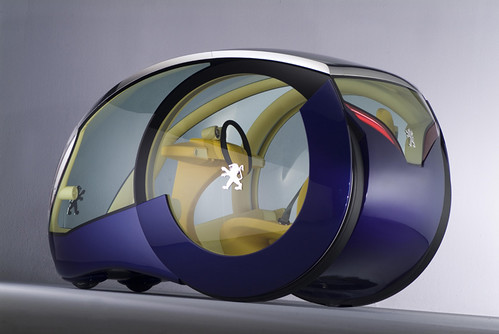

Peugeot Moovie

The Portugese designer André Costa took another novel approach to ease of city parking and manoeuvring. His design Moovie, made for the 2005 Concours de Design Peugeot, features two huge hub-less side-wheels which are used for both driving and steering.

Each wheel is independently driven by an electric motor, allowing the Moovie to rotate on its own axis and squeeze into the tightest parking spots. To increase stability, the two side-wheels are tilted inwards under a ten degree angle. The front-end conceals two small additional wheels which only operate as safety supports. In the future it could be possible to make such a vehicle self-balancing using gyroscopes and balance sensors. This is already employed on the Segway scooter and is suggested for the EMBRIO one-wheeled motorcycle concept.

The Moovie concept car built by Peugeot has a length of just 2,3 metres (7.6 ft) and width and height of 1,5 metres (4.9 ft). Access is created by two large sliding doors placed in the centre of the hub-less side-wheels.

(images courtesy: André Costa, Peugeot)

PERSONAL MOBILITY

Embrio: One-Wheeled Motorcycle

The EMBRIO Advanced Concept is a one-wheeled recreational and commuting vehicle for the year 2025, designed by the Canadian company Bombardier Recreational Products. Although the riding position is similar to that of a motorcycle, the vehicle uses sensors and gyroscopes to balance up to two passengers on a large single wheel whilst driving.

Images courtesy:Bombardier Recreational Products

Although the vehicle will also remain stable when motionless, with two small front wheels deployed at speeds below 20 kilometres per hour (12.5 mph). To move forward, the rider activates a trigger on the left handlebar. At a speed of 20 kilometres per hour (12.5 mph) the front wheels or "landing gear" retracts so the rider is balancing on the large single wheel. To turn the rider leans to the left or right. The brake is activated by a trigger on the right handlebar. Fuel cells running on hydrogen provide electricity for the electric motor which drives the single wheel.

TECHNICAL SPECIFICATIONS

MODEL NAME: EMBRIO Advanced Concept

DEVELOPED BY:Bombardier Recreational Products

STATUS: Concept

YEAR: 2003

DRIVE SYSTEM: Fuel cell electric

FUEL: Hydrogen

LENGTH: 1,240 mm (48.8 in)

WIDTH: 700 mm (27.5 in)

HEIGHT: 1,200 mm (47.5 in)

WEIGHT: 164 kg (360 lbs)

SEATING CAPACITY: 2

PUBLIC TRANSPORT:

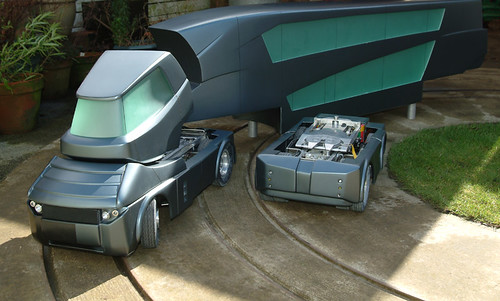

Blade Runner: Rail & Road Hybrid

Furthermore an interesting crossbreed between light rail and a bus is the Blade Runner concept, developed by the British company Silvertip Design. The Blade Runner is aimed to reduce traffic congestion as well fuel consumption and pollution by utilizing a dual-mode vehicle concept.

The Blade Runner is equipped with both road wheels with rubber tires as well as retractable rail wheels. This makes it possible for the vehicle to switch between driving on roads and fixed railway tracks embedded in a road surface. When running on such rails, the road wheels still provide the driving and braking power while the weight is carried by the track. This combined system makes the Blade Runner more versatile than a train and more fuel efficient than a truck. The fuel efficiency is due to the lesser rolling resistance between train wheel and track, compared to road-wheels, and improved aerodynamics.

Blade Runner can be configured to run along existing ballasted railway track, but will need additional pavement installed level with the rails for the vehicles to be able to get on and off the system. Embedded rail systems would typically provide access for the vehicles and the traction surface needed for the enhanced performance when approaching junctions. Such a track could be installed down the median of existing highways. For long-distance traveling the Blade Runner can run more efficiently on rails with a saving in fuel consumption of between 20 and 55 per cent, depending on the configuration.

When required, the vehicle can retract the train wheels in order to deviate from the railway and carry on by road to deliver and collect like an ordinary bus or truck. This ability to change from rail to road-mode greatly enhances the versatility of the Blade Runner. The vehicle can travel in automated, guided vehicle convoys or be manually driven.

The Blader Runner is under development by the British company Silvertip Design, which in 2004 built a fully functioning 1:8 scale model and is conduction tests on a specially built track. The project has so far been backed by the British freight trailer and body builder Don-Bur and the British government’s Department of Trade and Industry. Silvertip Design has furthermore built and tested a full sized semi-trailer truck fitted with a steering rear bogie used in the Blade Runner design.

TECHNICAL SPECIFICATIONS

NAME: Blade Runner

DEVELOPED BY: Silvertip Design

STATUS: Concept/functioning model

YEAR: 2004 (model)

DRIVE SYSTEM: Hybrid-electric with Diesel engine (front) + electric motor (rear)

MAXIMUM SPEED: 120 km/h (80 mph)

FUEL CONSUMPTION: 14 – 20 l / 100 km (16.7 – 11.8 mpg US)

EMPTY WEIGHT: 15 tonnes (16.5 ton US)

SEATING CAPACITY: 105 (double deck configuration)

70 + 35 standing (single deck configuration)

Images courtesy Silvertip Design.

Moller Skycar: VTOL Flying Car

The Skycar M400 is a flying car prototype which utilizes Vertical Take-Off and Landing (VTOL) technology. This makes it possible to take off and land without the use of an airport runway. The American company Moller International envisions a future where flying car owners can simply take to the skies directly from their driveway.

The Skycar M400 has seating capacity for four people, but its design can also be scaled up to the six-seating M600, or scaled down to the single-passenger M100.

The Skycar has a highly streamlined design equipped with four ducted-fan nacelles – two placed on either side of the cockpit. Each nacelle fully encloses the engine and fans and produces both lift and propulsion when airborne. Vertical lift is obtained during takeoff by redirecting the airflow downwards by deflection vanes inside of each nacelle.

Of great importance for the operation of a VTOL machine is a lightweight construction. Therefore the Skycar is constructed for a large part from fibre reinforced plastic composite material.

The Skycar M400 is equipped with eight rotary engines of the Wankel type with multi-fuel capabilities. These engines offer a high power versus weight ratio. For safety reasons four groups of two engines each power the four nacelles. If one engine fails, the fans can be driven by the back-up unit.

In flight the Skycar can achieve a cruising speed of 440 kilometres per hour (275 mph) and a maximum speed of over 600 kilometres per hour (375 mph). On the ground the Skycar is capable to travel short distances as an automobile. Maximum ground speed is limited to approximately 50 kilometres per hour (30 mph).

TECHNICAL SPECIFICATIONS

MODEL NAME: Skycar M-400

DEVELOPED BY: Moller International

DRIVE SYSTEM: Rotary engines

FUEL: Ethanol

FUEL CONSUMPTION: 11.8 l / 100 km (20 mpg US)

GROUND SPEED: 50 km/h (30 mph)

CRUISING AIR SPEED: 440 km/h (275 mph)

MAXIMUM AIR SPEED: 600 km/h (375 mph)

FLYING RANGE: 1,200 km (750 miles)

FLYING ALTITUDE: 11 km (36,000 ft)

GROSS WEIGHT: 1,090 kg (2,400 lbs)

Images courtesy Moller International.

WATER TRANSPORT:

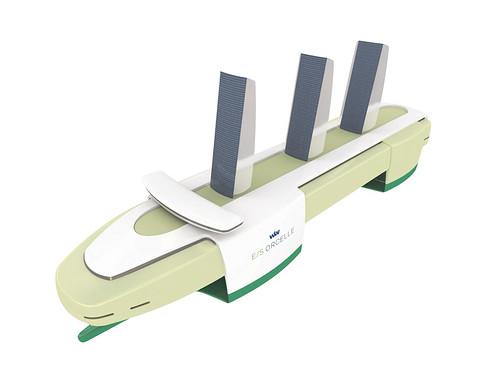

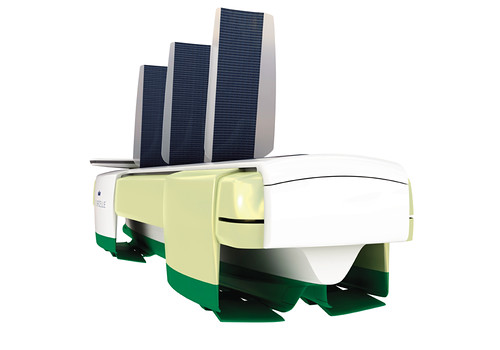

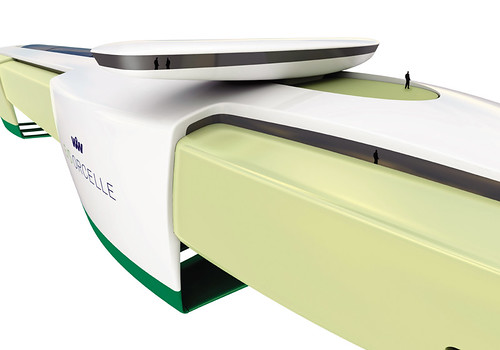

E/S Orcelle:

Powered by sun, wind and waves.

Wallenius Wilhelmsen Logistics developed the E/S Orcelle "Zero Emission Ship" concept for a ship which uses no conventional engines, uses no fossil fuels and releases no harmful emissions into the atmosphere or pollution into the sea. Aimed for the year 2025, the E/S Orcelle is powered by the three renewable energy sources available at sea: sun, wind and waves. With the concept, Wallenius Wilhelmsen Logistics wants to showcase what could be achieved given current and future technologies and a world devoid of fossil fuels.

The vessel is equipped with three large sails for wind propulsion. Each sail is constructed of a lightweight composite material and has a surface area of 1400 square metres (15,069 ft2). The rigid sails can be folded upward and outward as well as rotated about the masthead to fix the best position to extract wind energy through the creation of drag force or lift force, or a combination of the two. The front of the sails are fitted with solar cells. Each solar panel has a surface area of 800 square metres (8,611 ft2). When there is little or no wind energy available, the sails can be tilted, laid down or otherwise directed towards the sun for maximum solar energy collection.

The hull of the ship is furthermore fitted with a total of twelve fins, which harness and transform wave energy into hydraulic, electrical or mechanical energy. Each fin has a surface area of 210 square metres (2,260 ft2). The fins can also propel the ship, driven themselves by wave energy or by the electricity or mechanical energy available on board. Approximately half the energy on the E/S Orcelle will be produced by an on-board fuel cell system, which convert hydrogen fuel into electricity. Any additional electricity from the solar cells and fins can also be stored and converted into hydrogen.

Electricity generated by the fins, solar cells and fuel cells is used to power two variable speed electric pod propulsion systems. One pod is fitted at each end of the main hull, replacing the traditional stern propeller and rudder and requiring less power. Each pod houses an electric motor, gearbox and propeller in a single unit able to provide full power and 360-degree maneuvrability.

Besides the streamlined and slender main hull, the E/S Orcelle has four support hulls. In combination with the fins, these support hulls provide extra stability at sea, eliminating the need for the vessel to take on and release ballast water. The ship is made from aluminium and plastic composites. The E/S Orcelle is designed as a car carrier with a capacity of 10,000 cars on its eight cargo decks and a cruising speed of 15 knots (28 km/h or 17 mph).

TECHNICAL SPECIFICATIONS

MODEL NAME: E/S Orcelle

DEVELOPED BY: Wallenius Wilhelmsen Logistics

STATUS: Concept

YEAR: 2005

DRIVE SYSTEM:

Sails + fins + electric motors

ELECTRICITY GENERATION:

Solar cells + fins + fuel cells

FUEL: Hydrogen

POWER OUTPUT:

Solar panels: 2,500 kW

Fuel cells: 10,000 kW

Pods: 2 x 4,000 kW

CRUISE SPEED: 15 knots (28 km/h or 17 mph)

MAXIMUM SPEED: 20 knots (37 km/h or 23 mph)

OVERALL LENGTH: 250 m (820 ft)

HEIGHT: 30 – 40 m (98 – 131 ft)

BEAM MOULDED: 50 m (164 ft)

DRAUGHT: 9 m (30 ft)

CARGO DECK AREA: 85,000 m2 (915,000 ft2)

CARRYING CAPACITY: 10,000 cars on 8 decks

Images credit: Wallenius Wilhelmsen Logistics

CONTINUE TO PAGE 2 OF THIS ARTICLE

Article by Paul Schilperoord, Octopus Design for Dark Roasted Blend.

(want to become contributing writer? write to us, see guidelines here)

Permanent Link...

Category: Technology

Related Posts:

How to Become a (Real) Cyborg, Robotics News from Japan

Dark Roasted Blend's Photography Gear Picks:

0 comments:

Post a Comment